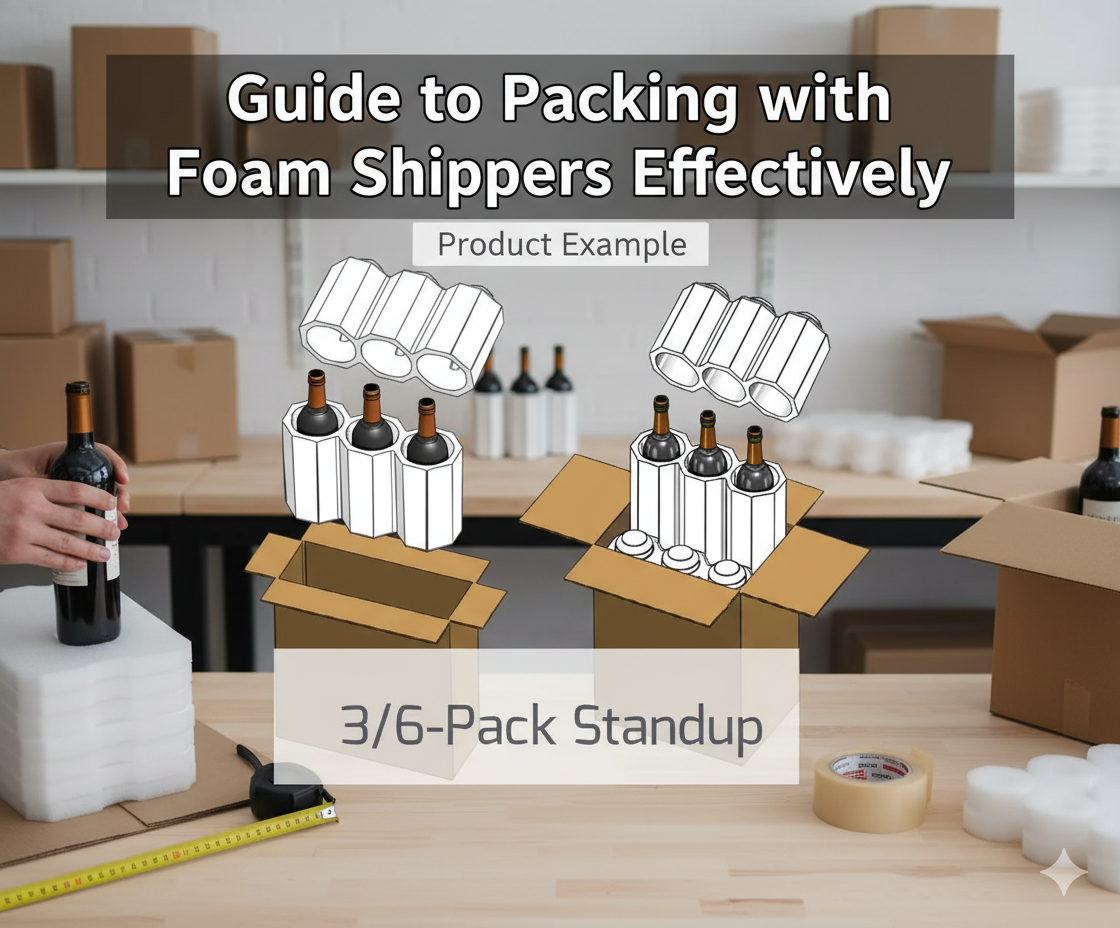

Guide to Packing with Foam Shippers Effectively

Foam shippers are an effective means of transporting delicate items. They safeguard bottles, jars, electronics, and glassware throughout the shipping process. This type of packaging is important if you deal with wine, cosmetics, or laboratory products.

Understanding Foam Shippers

Foam shippers use dense foam inserts to cushion products. The foam absorbs shock from handling and vibration during shipping. Each cavity fits the shape of your item, keeping it stable and protected. Foam shippers often include an outer corrugated box for added support.

Why Foam Shippers Are Effective

Foam packaging is popular for high-value or delicate products. The benefits include:

- Strong protection from impact and drops

- Lightweight structure for lower shipping costs

- Temperature insulation for sensitive goods

- Precise fit for glass bottles and jars

- Reusable and recyclable materials

Proper packing methods ensure these benefits work fully.

Step 1: Prepare Your Shipping Area

Organize your packing station before you begin. Keep all materials within reach. You will need:

- Foam inserts

- Outer shipping boxes

- Packing tape

- Labels

- Product sleeves or seals if required

A clean and organized space reduces packing errors.

Step 2: Inspect Your Foam Inserts

Check for cracks or dents in the foam before use. Damaged foam reduces protection. Replace any defective pieces. Properly sized foam ensures items stay secure and aligned.

Step 3: Position the Foam Base

Place the foam base inside the bottom of the box. Make sure it lies flat. This creates a stable foundation for your product. Uneven placement can lead to pressure on the bottles during transport.

Step 4: Load Your Products

Gently insert each bottle or item into its foam cavity. Ensure each fits snugly. Avoid forcing items in or leaving extra space. Loose products shift during handling and increase the risk of breakage.

For wine shipments, use foam inserts designed for standard, magnum, or half bottles. Match the size of your shipper to your bottle type for a perfect fit.

Step 5: Add the Top Foam Layer

Once loaded, cover the items with the matching top insert. This secures everything in place and prevents vertical movement. Make sure the lid closes evenly across all cavities.

Step 6: Seal the Box

Close the outer corrugated box and tape all openings. Use strong packing tape across seams for reinforcement. Apply extra tape along the bottom if the shipment is heavy.

Step 7: Label Your Package

Attach clear labels on the top and side. Include “Fragile” and “This Side Up” markings when shipping glass items. Proper labeling ensures careful handling by carriers.

Step 8: Test for Stability

Before shipping, lift and gently shake the box. Nothing should shift inside. If you hear movement, reopen and adjust the inserts. Secure packaging prevents accidents during sorting and delivery.

When to Choose Foam Shippers

Foam shippers are ideal for:

- Wine and beverage deliveries

- Pharmaceutical or laboratory products

- Perfume and cosmetics

- Electronic or optical items

They perform well in long-distance shipping or during temperature-sensitive transport.

Tips for Efficient Packing

- Use inserts that match your product dimensions.

- Store foam shippers in a dry place to preserve quality.

- Combine foam inserts with corrugated boxes for double protection.

- Train staff on proper loading techniques.

- Avoid reusing damaged or compressed foam.

Advantages for Your Business

Using foam shippers helps you save time and reduce returns. Customers receive their products intact, which builds trust. Consistent protection improves efficiency across your supply chain..